The features of the Industrial stainless steel mayonnaise making machine

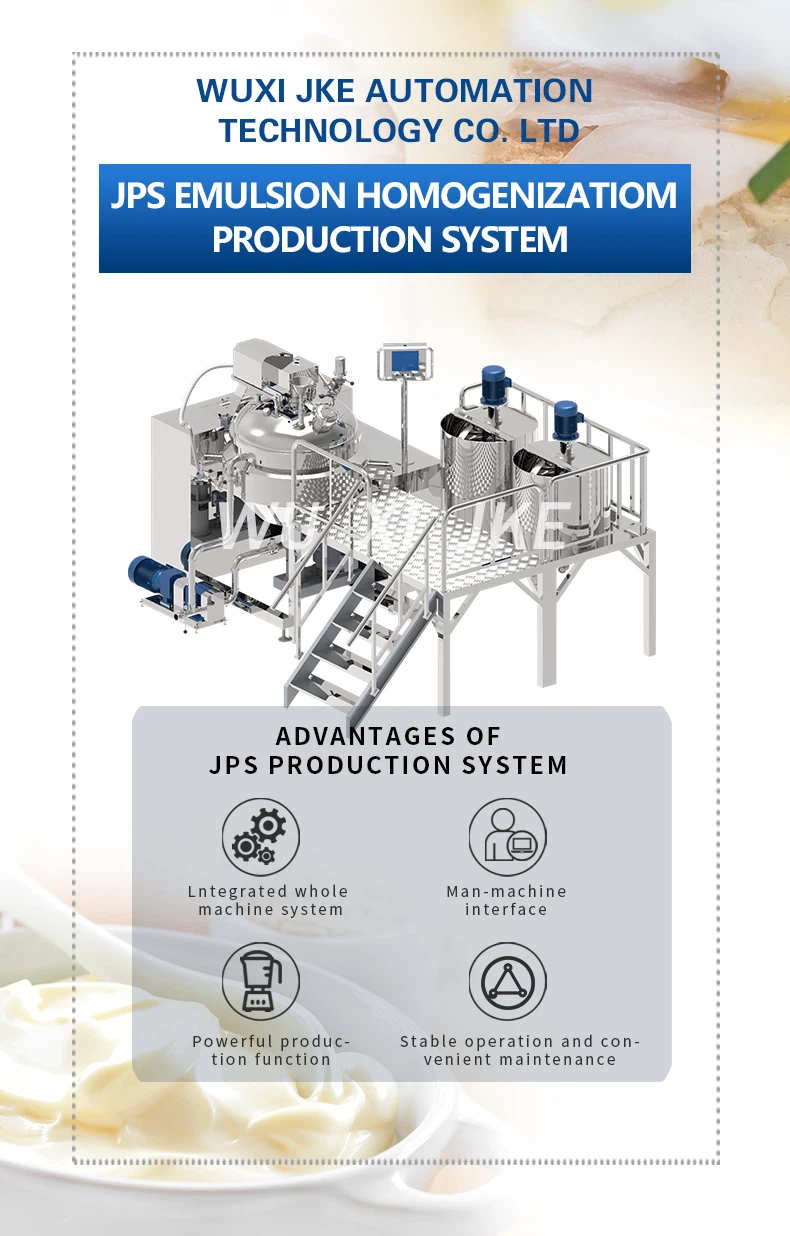

The production process of salad dressing and mayonnaise can adopt the alternate method, intermittent method or continuous method to make the two phases mixed and emulsified to form oil in water emulsion. When using the alternating method for production, the emulsifier is first dispersed in a portion of water, and then a small amount of oil and the remaining portion of water and vinegar are alternately added. Finally, the obtained primary emulsion is homogenized. When using a continuous production method, the water phase is mixed evenly with the emulsifier, and then the oil is gradually emulsified into the mixture under intense stirring. Continuous production is carried out in a vacuum emulsification machine, where vacuum is pumped while oil and vinegar are fed while stirring for emulsification. It is recommended to use Wuxi Jiangke's salad dressing emulsifier system for homogenization equipment.

To know more information about sauce/mayonnaise emulsifying machines,vacuum emulsifying machines for chemical or cosmetics,high shear batch homogenizer,emulsifying pump,powder liquid mixing pump,or mayonnaise production line equipments,please contact.

Tel/Whatsapp:+86 15261658912

Email:jkesales04@wuximixer.com

Hot Tags: industrial stainless steel mayonnaise making machine, China, suppliers, manufacturers, factory, custom, price, OEM, Mayonnaise Making Line, Vertical Stainless Steel Mayonnaise Making Machine, High Shear Homogenizer Machine, Emulsifier Homogenizer Mixing Machine, Mayonnaise Emulsifying Machine, Mayonnaise Emulsifier Mixing Machine